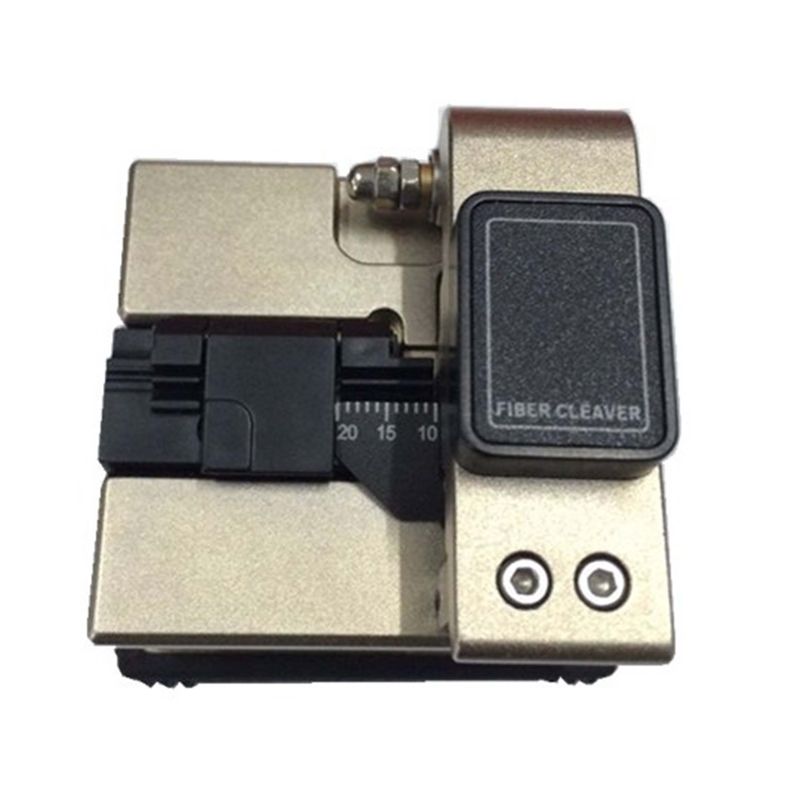

SOPTO’s Fiber Cleaver

A critical precision tool for optical fiber preparation, designed to deliver clean, accurate fiber cuts essential for reliable fusion splicing and fiber optic network deployment.

Product Overview

SOPTO's fiber cleaver represents the pinnacle of precision engineering for fiber optic preparation. This essential tool delivers consistently clean, flat cuts that are critical for achieving low-loss fusion splices and reliable fiber optic connections in both field and laboratory environments.

High-precision cutting for optimal splicing performance

Core Function

Enables high-precision cutting of singlemode and multimode fibers to ensure flat, smooth fiber end-faces, which is vital for minimizing insertion loss and optimizing splicing performance.

Precision Cutting

Consistently produces flat, smooth end-faces for singlemode (9/125µm) and multimode (50/125µm) fibers

Performance Optimization

Minimizes insertion loss and ensures reliable fusion splices with low attenuation

Key Features

Durable Cutting Blade

Long-life blade supporting hundreds to thousands of precise cuts

Ergonomic Design

Easy one-handed operation for enhanced productivity

Adjustable Parameters

Customizable settings for different fiber types and applications

Portable Construction

Compact design suitable for both fieldwork and laboratory use

Easy Maintenance

User-replaceable blade and simple calibration procedures

Rugged Build

Durable construction withstands field operation conditions

Applications

Fusion Splicing

Essential preparation tool for fiber fusion splicing operations

FTTx Networks

Ideal for FTTH and FTTB network construction and maintenance

Telecom/CATV

Vital for telecommunications and CATV network maintenance

Fiber Labs

Precision tool for fiber optic laboratory testing environments

Fiber Connections

Prepares fibers for various connector installations and terminations

SOPTO's fiber cleaver is an indispensable precision tool for any fiber optic installation or maintenance operation. Its ability to produce consistently clean, flat fiber end-faces directly contributes to lower insertion loss, better splice performance, and more reliable network operations. The ergonomic design and durable construction make it suitable for both field and laboratory applications.