The Essential Guide to Fiber Optic Patch Cords

Types, Technology, and Selection

Fiber optic patch cords, also known as fiber optic patch cables or fiber jumpers, are indispensable components in modern optical networks. They act as the critical link for interconnecting devices like optical switches, servers, and distribution frames. Understanding the various technical specifications of these seemingly simple cables is crucial for ensuring optimal network performance, low signal loss, and future scalability.

Core Technical Classifications

1. Fiber Mode: Single-mode vs. Multimode

The core difference lies in the diameter of the fiber core, which dictates how light travels and the effective transmission distance.

| Feature | Single-mode (SM) | Multimode (MM) |

|---|---|---|

| Core Diameter | Very narrow (typically 9/125 μm) | Wider (typically 50/125 μm or 62.5/125 μm) |

| Light Path | Allows a single path (mode) of light. | Allows multiple paths (modes) of light. |

| Distance | Long-distance transmission (up to kilometers). | Short-distance transmission (up to a few hundred meters). |

| Bandwidth | Higher bandwidth potential, especially over distance. | Lower bandwidth potential, subject to Differential Mode Delay (DMD). |

| Jacket Color | Typically Yellow (OS1, OS2) |

Orange (OM1, OM2) Aqua (OM3, OM4) Lime Green (OM5)

|

| Applications | Telecom, long-haul networks, enterprise backbones. | Data Centers, Local Area Networks (LANs). |

2. Connector Types

The connector ensures precise physical and optical alignment between the fiber ends. The most common types are:

LC (Lucent Connector)

Small Form Factor (SFF), push-pull mechanism. Highly popular in data centers for high-density installations.

SC (Subscriber Connector)

Square, snap-in connector. Widely used in Passive Optical Networks (PON) and simpler systems.

ST (Straight Tip)

Bayonet mount mechanism. Older design, still found in some legacy or industrial LAN applications.

FC (Ferrule Connector)

Screw-on thread mechanism. Ideal for high-vibration environments, though less common now.

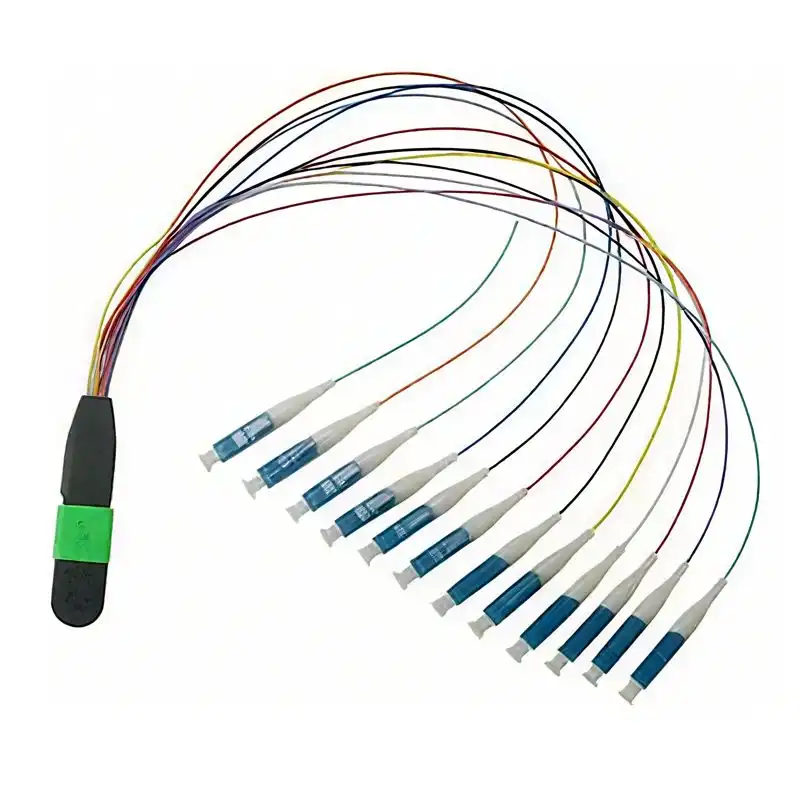

MTP/MPO (Multi-fiber Push-on/Pull-off)

Multi-fiber connector housing 8, 12, or 24 fibers. Essential for high-density, parallel optics (e.g., 40G/100G) in data centers.

3. Polish Types: PC, UPC, and APC

The quality of the connection is critically determined by the finish (polish) of the ceramic ferrule's end-face. This affects Return Loss (RL), which is the amount of light reflected back toward the source—a higher RL is detrimental to network performance.

Physical Contact: The end-face is polished slightly spherical to reduce the air gap.

Return Loss (∼−40dB).

Ultra Physical Contact: An extended, more refined polishing method for better surface finish.

Return Loss (∼−55dB). Most common for digital, non-video applications.

Angled Physical Contact: The end-face is polished at an 8° angle. This angle directs reflected light into the fiber cladding, minimizing back-reflection into the core.

Return Loss (∼−65dB). Essential for high-speed systems, CATV, and applications sensitive to back-reflection.

Essential Selection Criteria

Choosing the correct fiber patch cord is vital for network health. Key factors to consider include:

Mode Matching

The patch cord must match the cable plant (e.g., OM4 to OM4). Mismatching, especially using single-mode patch cords on multimode systems or vice-versa, will result in complete signal loss or severe degradation.

Connector Compatibility

The connectors must match the ports on the equipment or patch panel. Hybrid patch cords (e.g., LC-SC) are used when connecting devices with different port types.

Jacket Rating

Based on the installation environment:

- PVC (Polyvinyl Chloride): Standard indoor jacket.

- LSZH (Low Smoke Zero Halogen): Safer for confined public spaces, as it emits minimal smoke and no toxic halogens in a fire.

- OFNP (Optical Fiber Nonconductive Plenum): Highest fire-resistance rating, required for air-handling spaces (plenums).

Specialty Cords

- Bend-Insensitive Fiber (BIF): Designed to tolerate tighter bending radii with minimal increase in signal loss. Crucial for Fiber-to-the-Home (FTTH) and high-density racking.

- Armored Cords: Feature a steel sheath for rodent and crushing resistance in harsh environments.

Summary

Fiber patch cords are the unsung heroes of high-speed connectivity. Their proper selection and careful management—avoiding excessive strain, kinking, and ensuring connector cleanliness—are paramount to achieving a stable, high-performance optical network.